Cutting in Windows & Hatches

An easy accurate method

Click on pictures to see full size image

Easiest and most accurate way we have found to cut in a new window, door, or hatch is using a hole saw.

We weld up the frame in the shop first, then cut the trailer frame and weld the window or door frame into place. We only weld the interior face and the interior corners of the studs so there is no burn marks on the skin outside. We also use a damp towel to prevent heat transfer to the skin while welding.

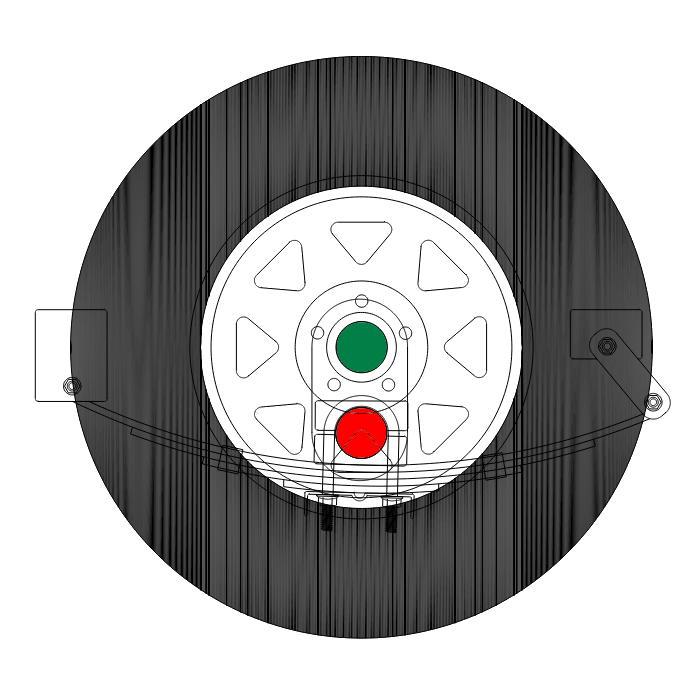

Find the correct diameter hole saw that corresponds to the radius of the windows corners while using the frame as a guide to locate the hole saw and cut all 4 corners in the outer skin from the inside of the trailer.

Usually the manufacturer will give you the radius in the details. For this window the corner radius was 3-1/8" so a 6-1/4" hole saw was the correct size.

Then hang the plywood inside and using the holes you already cut in the sheet metal, cut the same holes in the plywood from the outside using the hole saw. The holes in the outer skin and the metal frame will help guide the cutting of the plywood.

Then going back outside, use a straightedge to draw your cut lines between the outer edges of the holes you cut in the sheet metal with the hole saw.

We use an electric sheet metal shear to cut the sheet metal between the cut holes. (No need to tape edges with this method) This tool gives the smoothest and cleanest cut in the sheet metal. You may also use a jig saw (Be sure to tape the cut areas to prevent scuffing of your sheet metal) using the new frame as a guide but these can be more difficult to get a clean smooth cut, especially for the inexperienced.

For the inside or plywood side, we draw our cut lines the same as we did outside and typically use a cordless skill saw set to exactly the depth of the wood or slightly less so we do not cut into metal and dull the blade

After cutting the wood if the window or hatch does not fit perfectly you can use a grinder with a flapper wheel to carefully enlarge or clean up the hole so the window fits perfectly. The flapper wheel method is much easier than trying to cut with a saw again and gives a much better finish to the hole.

A flapper wheel can cleanup metal siding as well.

Baggage hatch for a Mini-Split

Windows in side doors

With foam core doors a jigsaw is your best bet due to the thickness of the one piece door

Horizontal windows

Vertical windows

Floor hatch for under floor storage